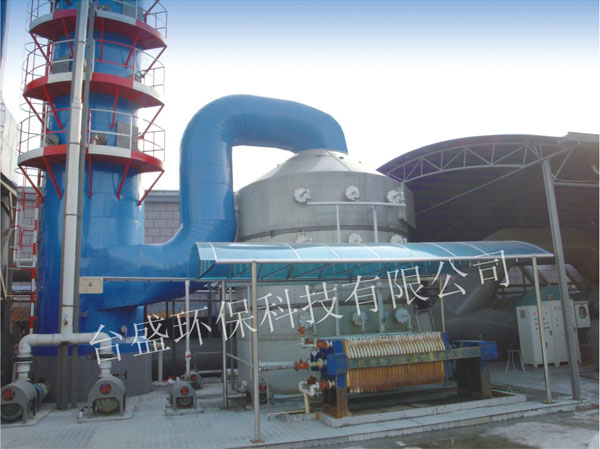

Desulphurization System

Position: TaiSheng > Desulphurization SystemDesulfurization System

Desulfurization technology (wet limestone/gypsum) used in thermal power plant and autonomous power plant.

This desulfurization method is a technology using lime or limestone as absorbent for flue gas desulfurization, desulphurization process produce by-product of gypsum which suitable for sales.

This technology is based on the change of the largest load, to meet power plant stringent requirements on operation and performance. After years of constant improvement, optimization on energy consumption, the loss of pressure, and availability, this process becomes more stable, excellence, has reached the world of the same class level. In the worldwide, from 10 MW to 1000 MW unit, burning all kinds of coal mine, lignite, heavy oil and others fire power station, all use this flue gas wet desulfurization technology.

Lime gypsum flue gas desulfurization system, this system is mainly used in the flue gas of large sulphur content (Usually 4000 PPm above), require to meet local emissions after desulfurization (Usually 400 mg/Nm3 below). This desulfurization system passes through scrubber for preliminary desulfurization and discharge slight dust from dust collector then proceed fine desulfurization by desulfurizer. All fans and pumps use one open one way, filtered by-product will be under board type filter press and vacuum belt filter processing, achieve zero emission requirements.

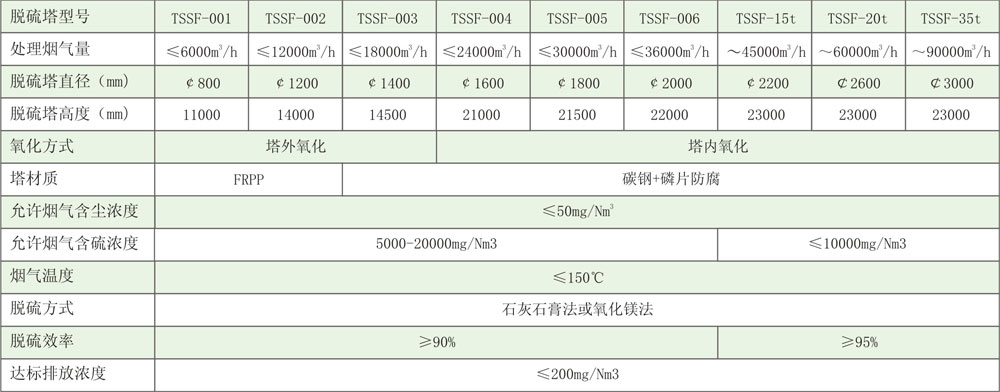

Param